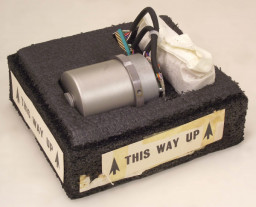

Inscription(s):

British Aircract Corporation

(G.W. Division)

Stevenage, Herts.

Rate-Integrating Gyro

NATO No. 6JA/1109882

Type No. RIG501/QB

Serial No. 10675

────────────────

[transport package label 1]

This item is to be handled with great care. It is not to be shaken at any time. It is important that item must be held in correct plane when packing and unpacking.

Notch must be at top

────────────────

[transport package label 2]

NSN: 6JA/6615-99-110-9882

Makers Part:

Desc.: Rate Integrating Gyro 501 QB

Batch:

Serial No.: 10675

Quantity: 1

Notes:

The given dimensions includes its foam plastic transport box; the gyro alone is: 51 x 70 x 51 mm, 269g.

In April 1958 English Electric acquired a licence to manufacture Honeywell gyros at Stevenage. English Electric Aviation Ltd became a founding constituent of the British Aircraft Corporation (BAC) in 1960 and the guided weapons division was added to BAC in 1963. In 1975 BAC bought out the future royalties for the Honeywell license. A rate gyro is a type of gyroscope, which rather than indicating direction, indicates the rate of change of angle with time. The gyro has only one gimbal ring, with consequently only two planes of freedom and is used to measure the rate of angular movement.

The Miniature Rate Gyro (MIG) employs a gimbal floated at neutral buoyancy in a fluorocarbon fluid and pivoted between jewelled bearings. The manufacture and assembly of such a gyro called for standards of precision unprecedented not only in industry but even in specialist laboratories. A crucial issue was vibration. The Instrument Wing was located between the Eastern Region main line to the north and the new Stevenage by-pass road, and further vibration came from machinery in the company's plant—and even from the footfalls of the staff. Accordingly, test equipment was mounted on concrete plinths carried on 50-ton concrete rafts supported on air bellows resting on heavy foundations deep in the earth.

The assembly and test area were clean rooms fully temperature and humidity controlled and it is the only miniature inertial quality gyro in production in Europe. These Gyros were used in inertial guidance systems for missiles and torpedoes for example.